The AIS GROUP FURNITURE CO., LTD located in Foshan city, Guangdong province is one of the leading furniture manufacturing companies in China. With 22 years' experience in the design, manufacture and distribution of integrated kitchen cabinets, bedroom wardrobes, bathroom vanities and other storage cabinets - AIS Group keeps a strong focus on product quality, which is the core value of our business. To ensure product quality, we source only top-quality materials from reliable suppliers who follow European Green Standard practices in order to provide customers with premium cabinetry products, and all our production processes are strictly Quality Controlled. We use advanced equipment for production and all workers are highly trained in the use of the equipment before they commence.

We are a leading OEM/ODM cabinet manufacturer in China. Our cabinets are made from the highest-quality materials and are available in a variety of styles and finishes, and cater to both residential and commercial customers. Plus, we offer a wide range of customization options to ensure that each customer gets the perfect product for their needs. Contact us today to learn more about our products and services! You won't be disappointed.

Our designer focuses on a range of cabinet design service to meet the specific needs of your interior decoration, and ensure your interior design can meet your desired effect.

We could provide different type of materials for you choose.Such as plywood, MDF, OSB, or chipboard. Chipboard is generally less expensive and more difficult to damage, but it also does not look as high-quality as plywood or solid wood. Other materials include the type of finish, hardware, and accessories.And high-quality kitchen cabinet materials are more resistant to wear and tear, and they are also less likely to suffer from structural damage. Not only will our kitchen cabinet last longer, but it will also look better. This is because premium materials are typically more aesthetically pleasing than lower quality materials.

Our designer focuses on a range of cabinet design service to meet the specific needs of your interior decoration, and ensure your interior design can meet your desired effect.

With our custom made cabinets, you can get exactly what you want without having to compromise, they cabinet can be customized to perfectly fit any space in your house.

We pack the cabinets by using the latest packing technology to ensure your items to be well protected, and efficiently arrange the delivery to ensure you receive the products timely.

Warranty & service can build customer’s confidence and trust in us, we always pay attention to their feedback, all these are the driving force behind improving the product quality.

AIS Group has 22 years' experience in design, manufacture of kitchen cabinets, bedroom wardrobes, vanities and other storage cabinets.We keeps a strong focus on product quality in order to provide customers with premium cabinetry products.

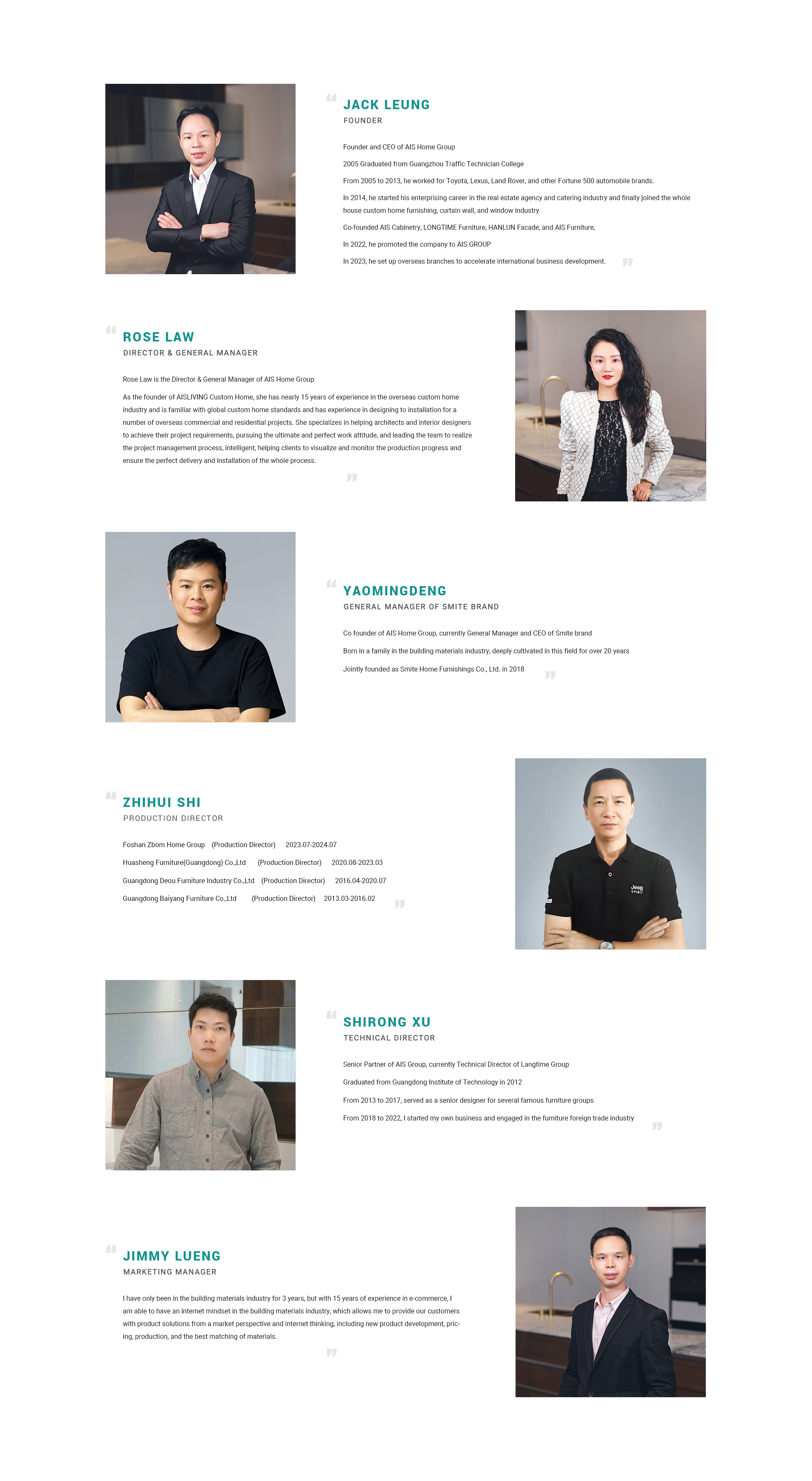

As AIS Group has developed for 22 years, it has become one of the leading cabinet manufacturers in China. At the beginning, the company was ran with a few employees as a small trading company. In the decade growing, AIS Group today already has 250 employees and 3 factories to meet the growing demand of the market, all of which are trying to make our cabinetry products with premium quality, and deliver our products to our customers in a short time period.

Our team has more than 20 years’ experience in the home furniture industry. We offer a complete service from planning, design and manufacture to delivery, installation and after sales service.

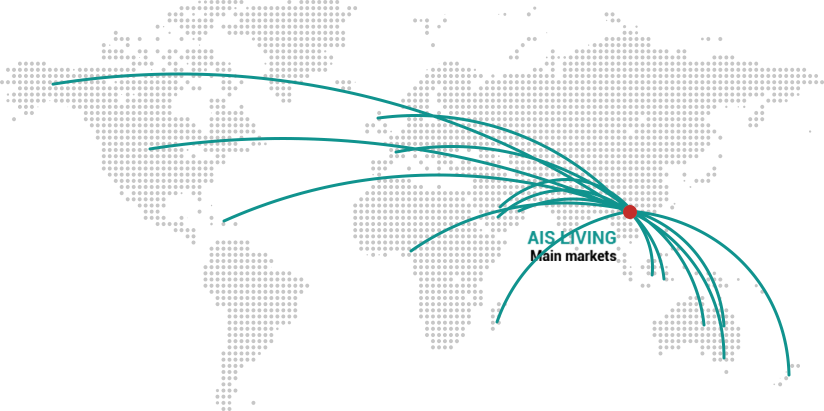

More than 70% of our products are exported, with flagship projects completed in Australia, America, Canada, UK, India, New Zealand, Philippines and South Africa. Our fashionable and high-quality products have gained the respect in domestic and overseas markets.

AIS Group's original designs and reasonable prices has allowed us to set up long-term business relationships with many customers all over the world. Our main markets are Oceania, North America, Europe, Middle East, Africa and Southeast Asia. We has an extensive experience of working with architects, developers, builders and contractors to develop high-quality and custom made cabinet solutions for any type of project, and we will always help customers create added-value to grow business.

This apartment project was one of the most sought-after neighbourhood in all of Windsor. It was a boutique development with only 80 units, and each one came with its own private balcony overlooking the river. The clubhouse was also something special -5,000 square feet of indoor and outdoor space for residents to enjoy. It was the perfect place to host gatherings with friends or family. When the sun begin to set, it’s the moment to admire the view from the balcony. The Detroit River stretched out before the apartment building, and the city skyline was a beautiful sight.

The Crowne Plaza Sydney Coogee Beach is one of the most iconic beach retreats in all of Sydney. Recently re-imagined, our hotel now reflects the coastal locale and its breathtaking panoramic sea views. Our location just steps from beautiful Coogee Bay provides guests with a connection to Sydney’s landmarks and a unique Australian experience.

If you are in the market for high-quality, beautiful villa kitchen cabinets and other furniture for your home, look no further than the furniture items available at 628 Nepean Highway in Frankston South, Australia. This stunning villa holds a range of kitchen cabinets, bathroom vanities, laundry cabinets, and more, all of which are sure to add a touch of luxury to your home.

Cabinet manufacturing processes typically involve cutting panels to size. This can be done using a variety of methods, including sawing, routing, and planing. Each method has its own advantages and disadvantages, and the best choice for a particular project will depend on the material being cut, the desired finish, and the production schedule. Sawing is often the fastest way to cut panels, but it can create a lot of dust and debris. Routing is a versatile method that can be used to create various shapes and finishes, but it requires careful setup and can be slow. Planing is an efficient way to create smooth, even surfaces, but it can be challenging to achieve tight tolerances.

Grooving is a cut made along the length of a workpiece, typically in wood or metal. Grooves are used for a variety of purposes in cabinet making, from creating decorative elements to accommodating hidden hardware. Grooves can be cut using a variety of tools and techniques, depending on the desired results. For example, a simple groove can be cut with a router or table saw, while more complex designs may require the use of a CNC machine. In addition to the type of tool used, the depth, width, and direction of the groove all play a role in the final appearance and function of the piece. As a result, grooving is an important part of the cabinet making process.

Edge banding is a common cabinet manufacturing process that involves adding a strip of material to the exposed edges of a piece of lumber. Edge banding can be used to cover up defects in the lumber, add strength to the edges, and improve the overall appearance of the finished product. There are many different types of edge banding materials available, including plastic, metal, and wood. Edge banding is typically applied using an adhesive, and the strip of material is then trimmed flush with the edge of the lumber using a router or other tool. In some cases, the edge banding material may be heat-activated, which will cause it to shrink slightly as it cools, creating a tight bond with the edge of the lumber.

Surface finishing is important in cabinet making processes to ensure a smooth and consistent look that will last for years. There are many methods of surface finishing, but the most common are painting, staining, and lacquering.

1. painting is the most versatile option, as it can be used to achieve a wide range of colors and finishes. However, it is also the most time-consuming option.

2.Staining is a quicker way to achieve a desired color, but it can be more difficult to achieve a consistent finish.

3. Lacquering is the quickest option, but it can be more difficult to repair if damaged.

In cabinet manufacturing, QC is essential in ensuring that the final product is strong and durable. There are a number of steps that are involved in QC, including materials testing, inspections, and reviews. Materials testing ensures that the components that will be used in the cabinet are up to standard. Inspections are conducted at various stages of the manufacturing process to identify any issues. finally, reviews are conducted after the cabinets have been assembled to ensure that they meet the required specifications.

Packing is the final step in cabinet manufacturing processes. It helps to protect the cabinets during shipping and handling, and it also prevents damage to the finish. Packing material should be soft and pliable, so that it can conform to the shape of the cabinet. Padding should be placed around all sharp edges, and special care should be taken to protect vulnerable areas such as door hinges. In addition, packing should be sturdy enough to withstand some minor bumps and scrapes. With proper packing, cabinets can arrive at their destination in perfect condition, ready to be installed and enjoyed.

1.First, if you already have kitchen cabinets design plans, you can send it to us. If you don't have kitchen cabinets design plans, you can tell us your kitchen room size and shape, floor to celling height, window & wall location, kitchen appliance size if you have, we will make a design for you.

2. We have many kitchen cabinets material, hardware, door style, countertop, toekick, packing for customers' options.

Option 1: We’re excited to hear from you! You can fill out a request form on our website here, it will immediately be forwarded to the appropriate sales representative, who will get back to you with some requirement questions for you within 24 hours (during business hours), you are asked to offer your kitchen dimensions, requests, or plan. Or you can email us at info@aishomegroup.com, or give us a phone call at +86-757-86436568.

Option 2: We’re happy to hear from you! We're here to help you find the perfect home! Fill out this form on our website, or give us a call at +86-757-86436568 if your preferred contact method is through email: info@aishomegroup.com. Our representative will get back to you within 24 hours (during business hours), there will be some questions about your dimension, material, and other requirements.

We always suggest customers to get a sample door to make sure they know how the cabinet is going to look and feel. The cost of samples will be determined by what materials and finishes required. We will credit the sample doors back to customers once they place bulk order from us.

At Ais Group Kitchens, we carry a wide range of high-quality, semi-custom and full customized kitchen cabinets. All of our cabinets are constructed and evaluated to meet requirements for ISO 9001 quality certification. Although choosing a quality manufacturer is essential, your final cabinet selection will ultimately depend on your taste, kitchen layout, and budget. The best kitchen cabinets are designed to last 20-30 years with proper installation. When planning your budget and kitchen cabinet design, that’s important to keep in mind.

Of course. First, think about the overall style of your kitchen. If you want a more traditional look, wood cabinets are a great option. For a more modern look, laminate or glass cabinets may be the best choice. Second, consider your budget. Wood cabinets are typically more expensive than laminate or glass, but they can also add value to your home. Third, think about how easy the material is to clean and maintain. Laminate and glass are both very easy to clean, but wood may require more care. Finally, ask our team of experts for advice. We can help you choose the best material for your kitchen based on your individual needs and preferences.

The most common materials used for cabinets are plywood, MDF, particle board, and OSB. Plywood is construction-grade lumber that's made by gluing together thin layers of wood veneer. It's strong, stable, and less prone to warping than solid wood, and it is ideal for use in cabinets.MDF is an engineered wood product that's made by breaking down hardwood or softwood into wood fibers and combining it with resin binders. MDF is dense and very smooth on one side, making it ideal for painting. Particle board is made from wood chips, shavings, and sawdust that are glued together with resin binders. It's less expensive than plywood but not as strong or durable. OSB is also made from wood chips, but they're Oriented horizontally and laid in alternating cross layers before being pressed and glued together. OSB is water-resistant but not as strong as plywood.

Option 1: For RTA models or standard finishes, it normally requires 20-45 days for lead time. For products required painting finishes such as veneer overlaid or lacquer, we need 40-50 days to finish. The accurate lead time would be determined by customization, extra time may be required.

Option 2: It normally requires 20-45 weeks for lead time on RTA models or standard finishes, but if you need painting finishes such as veneer overlaid or lacquer we would like 40-50 days anticipate that it will take longer due to customization which is why our accurate timeline depends heavily upon what type of customization request someone makes since extra time may be required at times.

For our Asian, American or European lines, delivery generally takes 10-15 days from the time the product is shipped. For African line, it generally takes 30-45 days.

Most of the items are needed to be made once order is confirmed. Stock items may be available due to different seasons, please contact our staff for detailed information.

1 Offer us the BOQ, drawing, & layout information.

2 We estimate the cost for you.

3. Negotiate on the design, material, price...

4. Confirm the order and arrange the deposit payment to us.

5. Start the production.

6. Arrange the balance payment to us.

7. Arrange shipment.

Option 1: If you need something changed or added, just let us know and we'll do what's best! However there may be some delays in production while we make those adjustments specifically tailored towards yours individual style preferences. If it is a item that has been specially created for your designs then unfortunately we will not be able to make the change for you.

Option 2: If you want a change, just let us know and we'll get right on it. However there may be some delays in changing those orders as they require very particular adjustments or measurements. With special items like tailored suits or parts of an order that have already been purchased, unfortunately we will not be able to make the change for you.

Option 1: To order our cabinets, 30% deposit paid by T/T (Telegraphic Transfer) before production, 70% balance before shipment. Payment by L/C is negotiable provided that credits of the buyer and issuing bank are audited by the supplier. For a sample or small amount under $1,000, payment can be made by Paypal or Cash.

Option 2: To order our cabinets, you need to make a 30% deposit before production. And the final 70% should be paid once your order is ready to ship from our factory in China! You can choose between different payment methods depending on how much money we're talking about - for small orders under $1k it's best if they come through with Cash or PayPal. Payment by L/C is negotiable provided that credits of the buyer and issuing bank are audited by the supplier.

Option 1: At AIS Group Furniture, we stand behind the quality of our products. That's why we offer a life time warranty on all our cabinetry products. We promise to take care of any problems related to manufacturing defects, missing items from boxes and warping. You can further review details on our limited warranty. So you can rest assured that your investment is protected.

Option 2: We offer a life time warranty on all our cabinetry products. We will take care of any problems related to manufacturing defects, missing items from boxes and warping . You can further review details on our limited warranty. This warranty does not cover any labor costs associated with installation or repair. Additionally, this warranty is void if the products are not installed in accordance with our instructions or if they are modified in any way.

We promise to every customer who buys kitchen cabinet products: fake one will be

fined ten, bad one will be compensated two, lifetime warranty.

1 We are confident with our quality that we can provide our life long warranty.

2 The above points show that the enterprise has a long-term vision in terms of service. Of course, the cost will increase accordingly

It's hard to say, there is no absolute, it mainly depends on how you use it, if you pay attention to

proper maintenance and care, our kitchen cabinets can be used for 15 to 20 years without any problem.

1.Online consultation-media platform,phone call

2.Negotiation at our company-make proposal based on requirement

3.Confirm intention-pay deposit,measurement service appointment

4.Measurement at site-Designer go to site to measure and discuss, take photo for record

For kitchen measurement:include the ceiling height, distance between walls, doors(include frame stopper),window height and width(include sill), window to floor/ceiling/wall corner distance, as well radiator, pipes, sockets,switches and drainage location, and exhaust fan outlet diameter

Color, material, handle etc, build your dream kitchen

1.Preliminary design-make drawing based on measurements

2.Discuss for modification-discuss with customer,optimize according to customer's requiement

3.Confirm drawing-make drawing for water pipe and electric wires based on confirmed drawing

4.Measure again-After Door frame, wall tiles, flooring, ceiling etc are completed, measurement the twice time

1.Confirm details-making production drawing, customer to confirm color, material, hardwares,sizes.

2.Sign contract-drawing,quotation,contract,all documents in duplicate,sign and stamp by both sides

3.Production-lead time is subject to contract

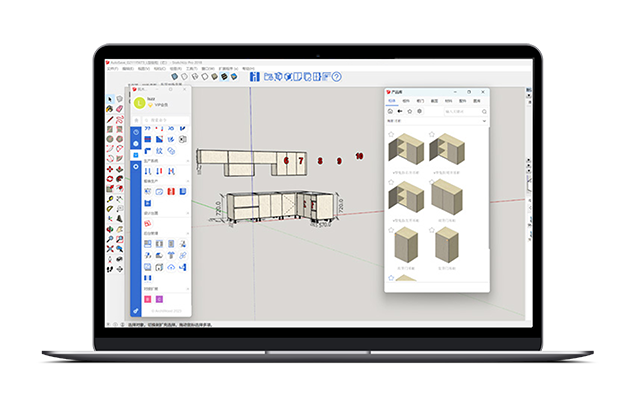

Enter all measurements in the software, choose house layout, then choosethe color and material you want to creat the house

After complete the kitchen rendering, you will get it in PDF format

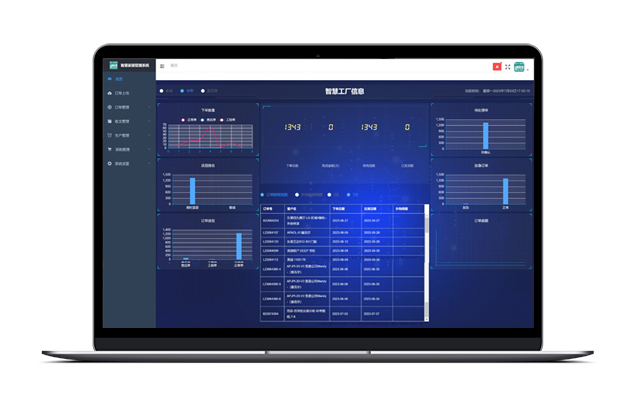

The production process is digitized, more efficient and more accurate, and the error rate is kept low in all steps of

Front-end sales system + SU design software + ERP production system

One-click output of production data

The system optimizes the typesetting of CNC, edge banding, hole arrangement, sorting, packaging, hardware and other data

1. Automatic loading and unloading platform

2. Straight row 16 tool magazine

3. Multi size machining

4. Flexible cutting

Electronic saw cutting

1. The system can interface with the order splitting software, with built-in optimization layout, saving materials and reducing waste

2. Batch cutting: particle board, plywood, MDF, OSB, etc

1. Door panel: PUR door panel edge sealing

2. EVA cabinet edge sealing

3. PET door panel laser edge sealing

4. 45 degree handleless drawer panel, door panel edge sealing

1. One processing can complete all six hole positions, achieving fast and efficient drilling and milling work

2. The screw transmission accuracy is higher, with an error within 0.05-0.1mm, and the cumulative error is small, which is higher than the rack transmission accuracy

3. Double sided alternating slotting: synchronous alternating slotting of the upper and lower sides, greatly improving production efficiency

4. Irregular machining: Cooperate with various cutting heads/drills to punch/slot/mill the sheet metal

1. Sort by order/unit cabinets' number using self-developed ERP system

2. Print labels for the board which label is missed or damaged to prepare for the next packaging step

3. To supplement orders with insufficient boards

4. Trial assembly: After assembly, measure the dimensions of the cabinet and board components, check the hole positions, and compare whether the actual object is relative to the drawings

1. Clean the board with board washing water

2. Check if there are scratches/damages on the boards

3. Use a color pen to repair the board

4. Replace the faulty boards

1. Using the ERP packaging system to scan codes,

2. Print packaging labels

3. Packing standard of panel: thick paper+foam+corner protection

4. Packing standard of fragile glass: thick paper+foam+corner protection+wooden creates

5. Baking paint packaging standard: thick paper+film covering+foam+corner protection

After packaging, deliver to the finished product warehouse, scan the code, count and enter the warehouse

Scan code, count and load

Provide professional technical personnel for on-site installation